Supply Chain Simulation – Demand, Safety Stock & Service Levels

| University | Technological University Dublin (TUD) |

| Subject | Logistics and Supply Chain Management |

Assignment:

- Choose one of the wholesalers

- Choose Service level (SL)

- Evaluate Safety Stock taking into account the demand uncertainty (estimate demand during lead time)

- Provide calculations and explanation

- Run a simulation experiment and observe the SL

- Explain simulation results

Problem solution

The simulation tool is Excel. You can solve this task in the PC class after the break.

Number of simulated lead time periods – 500

Random demand simulation using

=randbetween(min,max) function

- Simulate daily demand d for three particular days

- Calculate demand at lead time DL for L=3 as a sum of three independent daily demand values

- Repeat the calculations 500 times

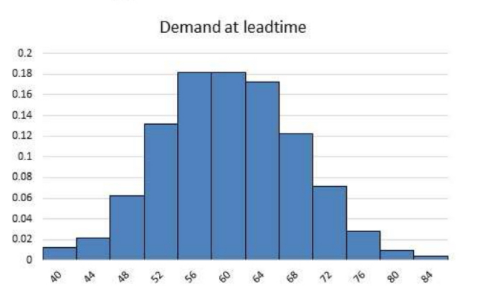

- Design a histogram of DL

- Evaluate the safety stock for 95% SL

Histogram creation from simulated data

Simulation results

| Simulation number | Demand at Wholesaler | |||

|---|---|---|---|---|

| First day | Second day | Third day | Demand at Lead Time (sum of all) | |

| 1 | 19 | 16 | 28 | 63 |

| 2 | 20 | 23 | 15 | 58 |

| 3 | 17 | 26 | 23 | 66 |

| 4 | 20 | 20 | 15 | 55 |

| 5 | 18 | 24 | 23 | 65 |

| 6 | 14 | 21 | 17 | 52 |

| 7 | 22 | 24 | 18 | 64 |

| 8 | 21 | 24 | 16 | 61 |

| 9 | 25 | 13 | 13 | 51 |

| 10 | 14 | 14 | 23 | 51 |

| 11 | 22 | 14 | 12 | 48 |

σDL = 8.03

Are You Searching Answer of this Question? Request Ireland Writers to Write a plagiarism Free Copy for You.

Histogram creation from simulated data

Data table (may be created using EXCEL array function Frequency or Data Analysis tool Histogram):

| Bin | Lower bound | Upper bound | Number of DL observations | Histogram of simulated DL |

|---|---|---|---|---|

| Demand at leadtime | ||||

| 1 | 36 | 40 | 6 | 0.012 |

| 2 | 40 | 44 | 11 | 0.022 |

| 3 | 44 | 48 | 31 | 0.062 |

| 4 | 48 | 52 | 66 | 0.132 |

| 5 | 52 | 56 | 91 | 0.182 |

| 6 | 56 | 60 | 91 | 0.182 |

| 7 | 60 | 64 | 86 | 0.172 |

| 8 | 64 | 68 | 61 | 0.122 |

| 9 | 68 | 72 | 36 | 0.072 |

| 10 | 72 | 76 | 14 | 0.028 |

| 11 | 76 | 80 | 5 | 0.01 |

| 12 | 80 | 84 | 2 | 0.004 |

Safety stock as a percentage of lead-time demand

Service level agreement is 95% (0.95 probability that the ordered goods are available at stock)

i.e. ~4.2% of DL values are larger than average + SS (or 58.6 + 17).

Calculated assuming that our DL is normally distributed

DIC_XIM

A SUPPLY CHAIN SIMULATOR. Parameters

| Factory warehouse | Distribution center | W1 | W2 | W3 | |

|---|---|---|---|---|---|

| Warehouse capacity | 4000 | 1000 | 200 | 200 | 200 |

| Initial inventory | 2000 | 200 | 50 | 20 | 20 |

| Transportation time L | 8 | 3 | 3 | 3 | |

| Backorder | No | No | Yes | ||

| Backorder cost | 4.5 | ||||

| Fixed order costs Ca (administrative costs) | 700 | 40 | 40 | 40 | |

| Holding costs (per day) Ch | 0 | 0.75 | 1 | 1 | 1 |

| Holding costs (Overstock) | 0 | 1.5 | 2 | 2 | 2 |

| Average demand D | 20 | 6 | 5 | ||

| Costs of goods sold/price | 72 | 115 | 115 | 115 | |

| Trucks | 2 | 5 | |||

| Truck capacity | 260 | 100 | |||

| Truck costs | 18 | 5 | |||

| Fixed period costs (per day) | 70 |

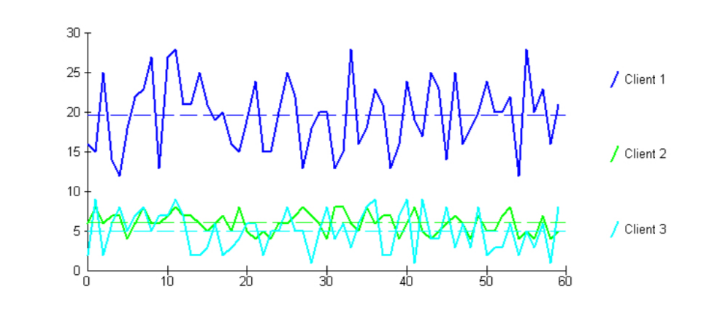

A Supply Chain Simulator. Dayly Demand

- Demand per Period (Day)

W1 Uniform between 12 and 28 W2 Uniform between 4 and 8 W3 Uniform between 1 and 9 - Client 1

- Client 2

- Client 3

Get Solution of this Assessment. Hire Experts to solve this assignment for you Before Deadline.

A Supply Chain Simulator Safety. Stock

- Choose one of the wholesalers

- Choose Service level (SL)

- Evaluate Safety Stock taking into account the demand uncertainty (*estimate demand during lead time)

- Provide calculations and explanation

- Run a simulation experiment and observe the SL

- Explain simulation results

- Provide your individual report with conclusions in ORTUS by the next lesson

A SUPPLY CHAIN SIMULATOR. Demand during lead time

Estimate demand during lead time:

- Demand during lead time (DL) is a random variable with unknown distribution function;

- Lead time is known and is constant;

- Reorder period and Lead time are not the same and may be different.

- DL distribution function can be estimated theoretically or by Excel simulation; Use the distribution from the previous practical assignment “Safety Stock”

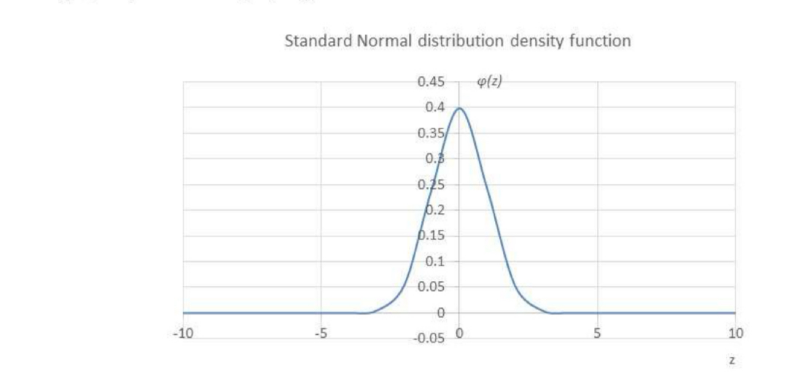

- To use the calculations provided in the lecture we need to confirm that DL is a normally distributed random variable;

- For safety stock calculation we need the mean value of DL and the demand standard deviation σDL;

- After Safety Stock calculation we need to formulate the strategy principles for implementation with the SC simulator to provide the necessary SL.

Service level agreement is 95% (0.95 probability that the ordered goods are available at stock)

≈ 17, i.e. ≈ 4.2% of DL values are larger than average

+ SS (or 58.6+17).

Calculated assuming that our DL is normally distributed

Standard Normal distribution

Excel function = NORM.DIST(z value, 0, 1, FALSE)